TEST FRAMES

Rigid and precise mechanical design

Exceptionally rigid frames feature custom extrusion designs, engineered for stiffness. Factory compensation of test frames and force sensors ensure position accuracy of ±0.002 in / 0.05 mm under any load, at any position.

Stepper motors and controllers drive a ballscrew and linear guideway for smooth, quiet operation, with virtually no speed variation under load.

Seamless force sensor interface

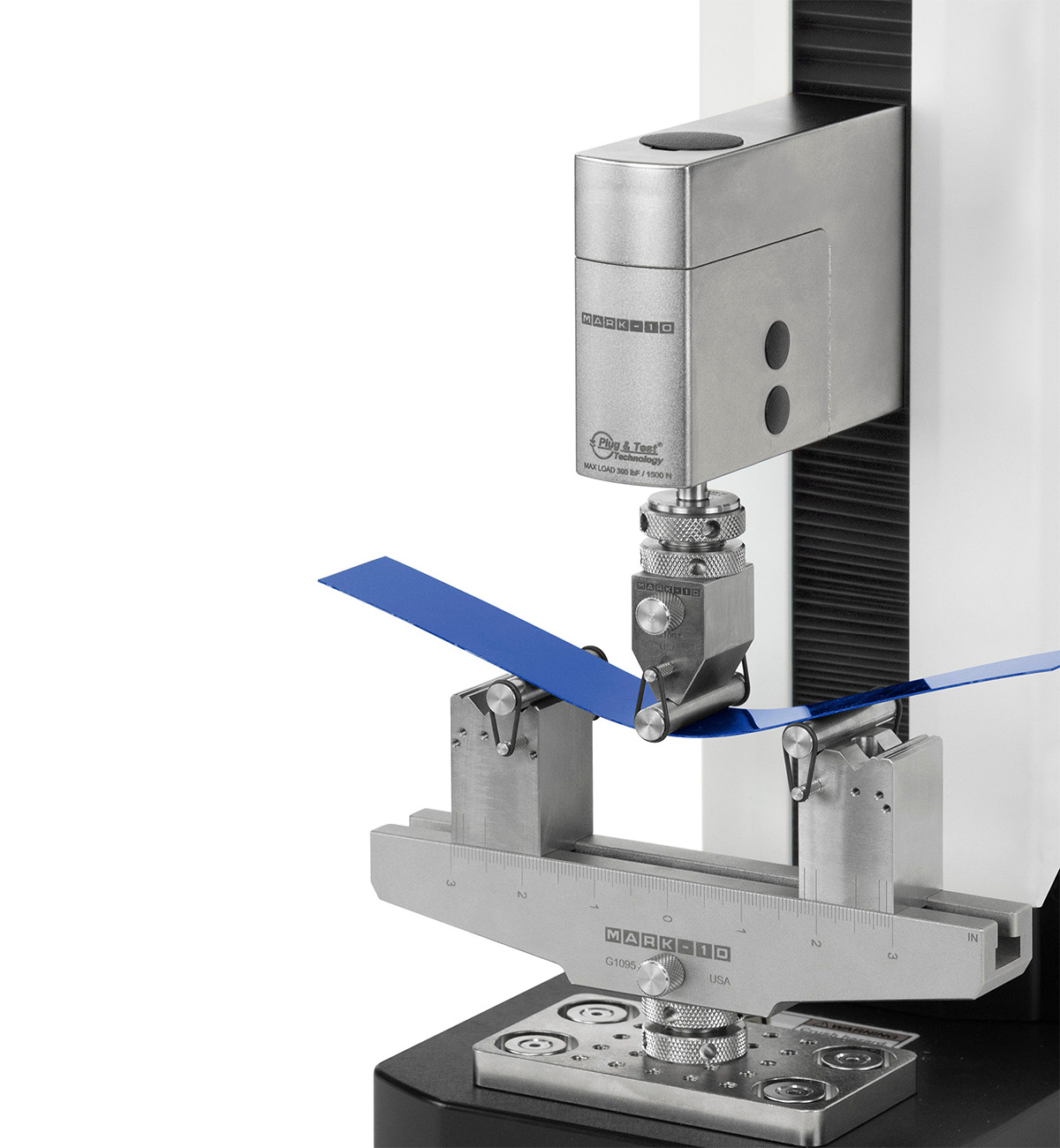

Series FS05 smart force sensors mount directly to the crosshead of models F105, F305, F505, and F505H, without any connecting cables. Ranges available from 0.12 to 500 lbf [0.5 N to 2.5 kN]. Accurate to ±0.1% of full scale.

Series FS06 force sensors accommodate larger and heavier grips and fixtures and are compatible with models F105, F305, F505, and F505H. Ranges are available from 50 to 500 lbf [250 N to 2.5 kN]. Accurate to ±0.15% of full scale.

Series R07 S-beam type force sensors accommodate higher force ranges, also compatible with Plug & Test® technology. Designed for models F755, F755S, F1505, and F1505S. Ranges available from 50 to 1,500 lbf [250 N to 7.5 kN]. Accurate to ±0.15% of full scale.

Modular design

Frame bases can be removed to accommodate column extensions and alternative mounting configurations. Most electronics are housed in a self-contained enclosure, easily accessed and replaced if needed. Integrated T-slots along the column accommodate add-ons, such as a USB hub.

External limit switches

Solid-state upper and lower limit switches may be used as test limits or as test exceptions. Dual-graduated rulers aid in switch placement.